Case study: Deutsche Bahn

Saul Matthews | 3 minute read | 06 December 2021

Affordable, resilient monitoring of overhead power lines

In 2021, Synaptec completed their trial with Deutsche Bahn (DB) to implement a radical new Distributed Electrical Sensing (DES) platform, as part of a DB mindbox program. Passive sensors were deployed to locate and characterise the impact of train movements on overhead power lines.

The trial demonstrated the potential for DES to implement rapid detection and protection of faulted sections, early warning of failure modes, danger alarms, and pantograph anomalies.

Improve uptime

Prevent failures and ensure continuity of service

Accurate monitoring

Identify passing trains to detect pantograph anomalies

Instant alarms

Warning of dangerous loss of tension in the contact wire

Deutsche Bahn (DB) is a German state-owned rail company who serve 1.87 billion passengers, and transport 197.6 million tonnes of freight across the longest rail network in Europe annually.

DB mindbox is an initiative devised by DB to connect technology companies to their in-house experts to drive innovation. The platform provides live test environments to generate real data, which helps accelerate these new and cutting-edge technologies.

The challenge

Operating a national, complex rail network means that DB are faced with many challenges that utility operators also come up against. With billions of customers relying heavily on their daily operation, it is imperative that DB maximise capacity safely, whilst reducing operating costs.

With over 40,000 km of electrified rail in Germany, DB recognised the need to embrace new technologies to maintain and improve service, overcoming the limitations of manual inspection of critical electrical and infrastructural assets which are often remote or hard-to-reach.

Synaptec worked with DB to retrofit their unique DES and Distributed Mechanical Sensing (DMS) technologies to provide early warning of failure modes in their Overhead Line Equipment (OLE) and power system assets to avoid costly outages.

Electrified rail networks require particularly high uptime and robustness to deal with increasing demand and availability of service, but are subject to electrical and mechanical failure risks, including contact wire sag, pantograph strikes, contact wire degradation and fatigue, electrical faults and flashover. Detection and management of all of these issues currently relies on scheduled manual inspection and maintenance of OLE infrastructure, which is expensive, infrequent, and halts revenue-generating traffic.

Our solution

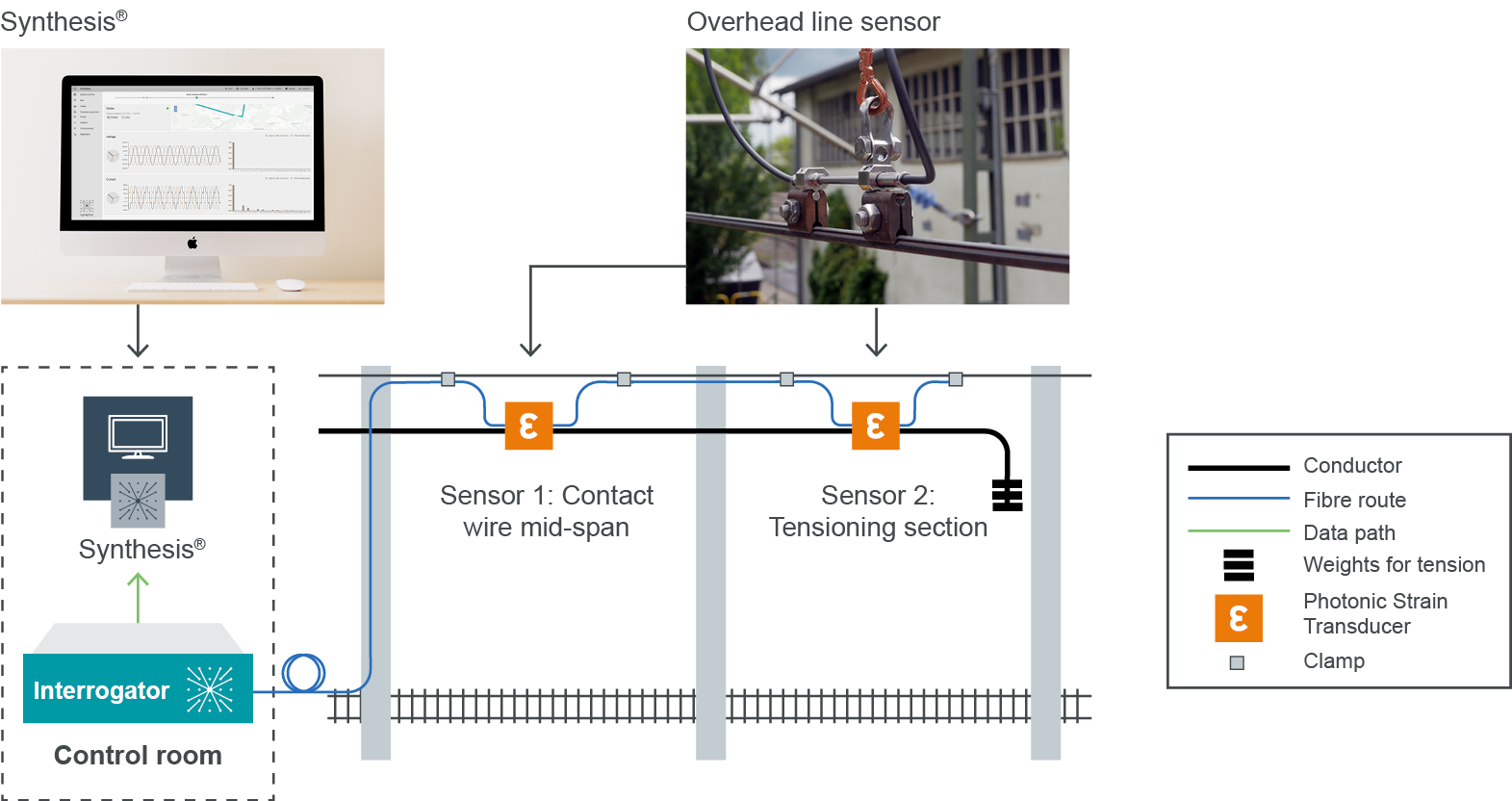

Synaptec’s DES platform offers permanent and highly detailed measurements across long distances to provide early warning of failure modes using a combination of interchangeable, passive electrical and mechanical sensors over a range of up to 60 km from the central Interrogator, using only safe, dielectric single-mode optical fibre.

Synaptec worked with DB to develop a unique optical strain gauge for installation directly on the contact wire for monitoring of strain, vibration, line sag and local temperature, enabling a host of new functions, including:

- • Rapid detection, characterisation, localisation, and protection response to electrical faults

- • Asset Group Analytics to identify impending failures, inefficiencies, degradation and loss of power in real time

- • Alarms to warn of dangerous loss of tension in the contact wire

- • Accurate monitoring of passing trains to detect pantograph anomalies

When combined with Synaptec’s existing portfolio of sensors for measurands such as current, voltage, temperature, vibration and strain, their technology offers synchronous and permanent electrical and mechanical monitoring of sectional electrical supply, rails, and OLE on transport networks anywhere.

Interoperable sensors can be installed in groups of up to 30 per fibre over a distance of up to 60 km from central Interrogators, without the need for control power, data networks or ongoing maintenance at the point of measurement. As they are passive, low-footprint and lightweight, Synaptec’s sensors enable live visibility and control from the most remote or inaccessible locations, without the need for ongoing maintenance.

Installation overview

Book a demo

Our solutions provide real-time, actionable insights to improve reliability and reduce operational costs. Discover how Synaptec can enhance your power system monitoring by speaking to one of our team today.

Applications

Related posts

Primary Current Transducer (PCT)

Synaptec’s Primary Current Transducer (PCT) combines industry-standard current transformers (CTs) with Distributed Electrical Sensing (DES) technology, enabling remote circuits to be instrumented passively without data networks, control power, or expensive civil...

Synaptec announces million pound sensor system order from Proserv

Unique sensor technology to be integrated into ECG™, Proserv’s holistic subsea cable monitoring system for offshore wind. Synaptec Ltd, the Scottish supplier of passive electrical monitoring systems for power networks, today announced that it has received a...

Distributed Electrical Sensing (DES)

We reduce outage and operational cost with the world’s only distributed sensor technology for operators of complex power systems. Our passive sensors require no power or data networks, and provide live data more reliably and securely from more locations than...