Monitoring overhead lines for sag, and dynamic line rating (DLR)

Reduce operational and maintenance costs with Synaptec’s unique overhead line sensors.

MV-HV power operators often run into maintenance issues with overhead power lines often located in hard to reach places. Synaptec can reduce operational costs with our unique, passive overhead line sensors.

Get in touch

Slava Tavoletti

Business Development

Jeff Williamson

Business Development

North America enquiries

Saul Matthews

VP Global Sales

Challenges in overhead line monitoring

Overhead power lines are required to reach the most remote or inaccessible locations, often traversing very different weather systems. This presents both operational and maintenance challenges for operators.

Operational challenges

From an operational perspective, the challenge is Dynamic Line Rating (DLR), and to know the line ampacity, or its safe thermal limits at critical points along the route in real time. This is influenced heavily by variable weather conditions, principally wind velocity and solar radiation, and by the circuit load current.

Maintenance challenges

From a maintenance perspective, the challenge is the cost and low frequency of manual inspection visits to identify potential failures, such as storm damage, ice accretion, or hotspots from conductor fatigue.

Our Solution

Our passive sensors are ideal for automating both monitoring tasks in one system, providing earlier warning of failures in remote locations, compared to conventional technologies.

Synaptec’s unique, passive sensors are retrofittable to any number of individual conductors and towers to give live and detailed visibility of sag, vibration, and temperature. By correlating mechanical measurements from our line-mounted sensors with electrical current monitoring, we provide true DLR with a more detailed, instantaneous and localised view of ampacity than weather forecasts for a general area.

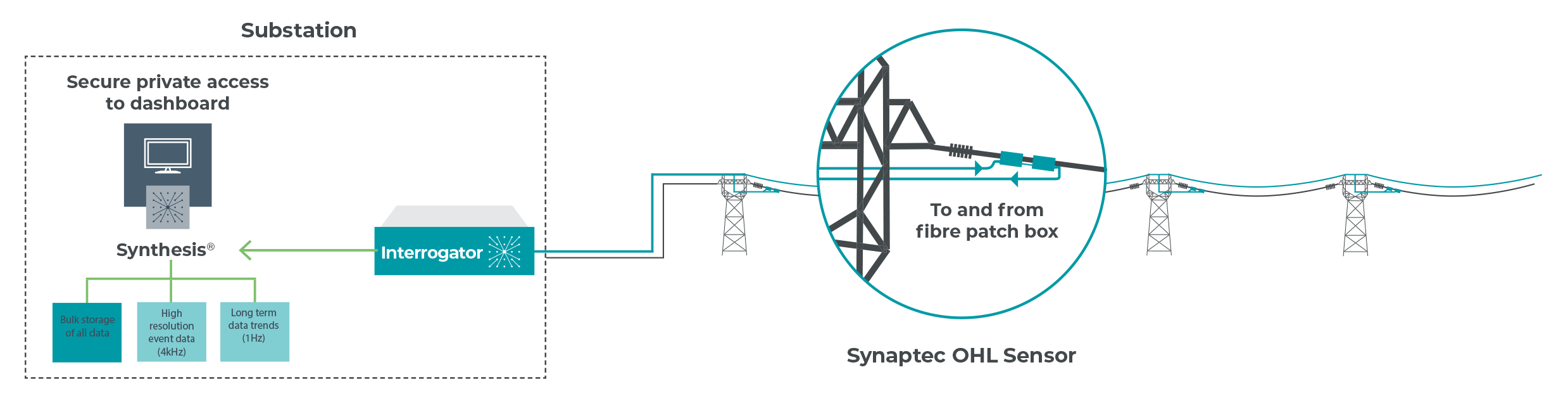

Without any need for control power, data networks or expensive civil works, our passive sensors can be deployed safely and rapidly anywhere. We provide real-time, synchronous, and permanent monitoring of temperature, vibration, strain, current, and voltage in the same system. This early warning enables more efficient maintenance, and location-specific validation of ampacity estimates derived from weather data.

Why the Synaptec solution is different

Live correlation of current, voltage, temperature, vibration and strain in one scalable condition monitoring and visualisation system

Requires no data networks, control power or expensive civil works

No ongoing maintenance (e.g. batteries)

Sensor lifespan of 25+ years

No periodic calibration

Integrates with SCADA and third-party data for DLR forecasting

Easily retrofits to any MV or HV line

Connected via single mode fibre (e.g. OPGW or ADSS)

All measurements are time synchronised

Download Overhead Line Monitoring flyer

Applications

Related posts

Overhead Line Sensor (OHLS)

Synaptec’s Overhead Line Sensor (OHLS) combines multiple high-performance optical measurement techniques into one completely passive device, enabling remote circuits to be instrumented without data networks, control power, or expensive civil works.

Distributed Electrical Sensing (DES)

We reduce outage and operational cost with the world’s only distributed sensor technology for operators of complex power systems. Our passive sensors require no power or data networks, and provide live data more reliably and securely from more locations than...

Overhead Line Monitoring

We reduce outage and operational cost with the world’s only distributed electrical sensor networks for operators of complex MV-HV power systems. Our passive sensor arrays require no 4G signal, no power supplies, or data networks, and provide live data more reliably...