Avoid subsea power cable failure with Synaptec

Earlier warning of more failures, in more locations than conventional monitoring.

Let us know your cable monitoring challenges and we’ll provide the solution.

Why Synaptec?

Globally adopted by leaders in the power grid & industrial sectors, now a key technology in renewable projects.

Zero-power &

zero-maintenance

Real-time visibility

and control

Significantly reduce outage costs

Synaptec & Offshore wind

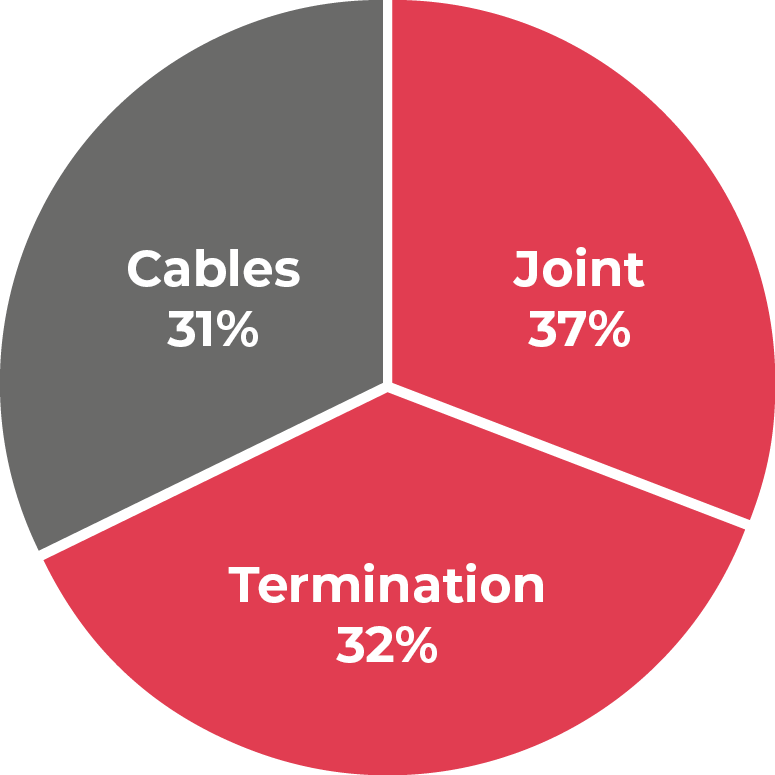

69% of all power cable failures occur in the joints and terminations, and these vital locations are overlooked by conventional monitoring.

Because Synaptec sensors are passive and require no power supplies, data networks or maintenance, they are ideal for monitoring joints and terminations, providing earlier warning of all three types of impacts which cause accelerated degradation in cable insulation.

Source http://www.jicable.org/TOUT_JICABLE/2015_slides/2015-D9-2_slides.pdf

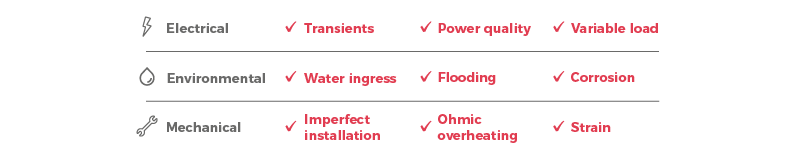

Earlier warning of all three types of impacts

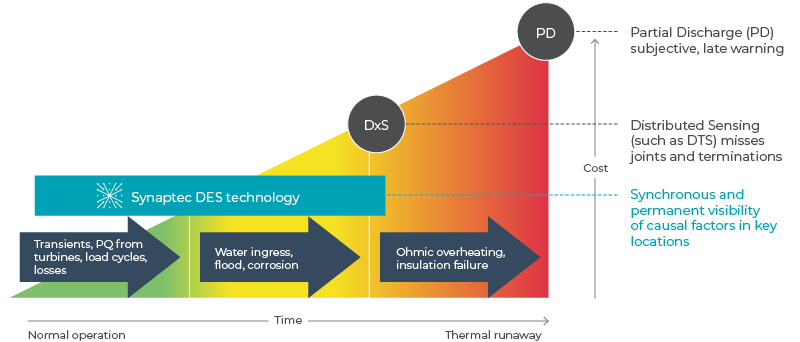

Synaptec sees the causes of failure long before conventional technologies see the results, such as thermal runaways or significant partial discharge.

Synaptec’s Distributed Electrical Sensing (DES) sees causal factors earlier

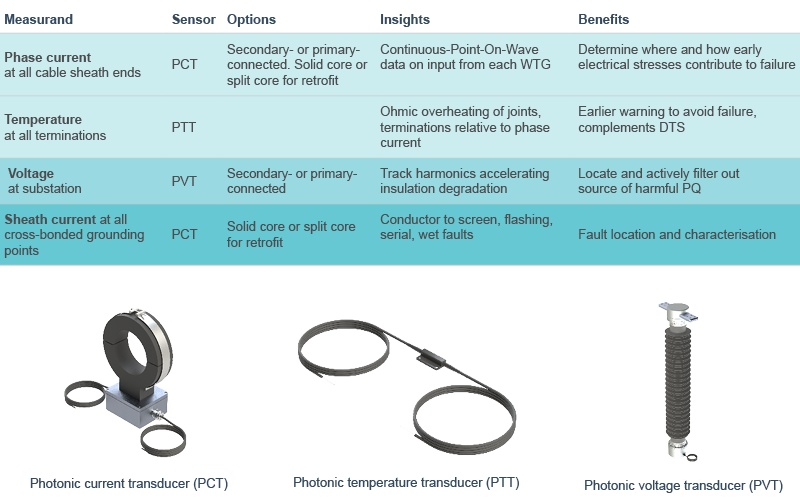

Only Synaptec can fit new or easily retrofit completely passive sensors to array cables to provide:

- Automated fault response

- User-defined threshold alarms

- More granular and accurate RTTR

- Distributed, permanent and synchronous Power Quality monitoring of each turbine

- Odd-Man-Out analytics for earlier intervention and fault avoidance

Platform architecture and benefits

Our solution

A scalable platform which can offer:

Termination temperature relative to phase current

Distributed Power Quality

Sheath current monitoring

Seamless integration with DTS, DAS and other useful sources such as metocean data

Holistic, integrated monitoring and reporting and prognostics

Measurands, insights and benefits