Offshore cable condition monitoring

69%* of all cable failures occur in joints and terminations, locations which are remote and inaccessible in offshore wind farms. As Synaptec sensors require no data networks or control power, it is now feasible to instrument these remote locations to provide early warning of more cable failure modes than with conventional technology. This dramatically improves availability and safety, while reducing OpEx and outage cost over the life of the array.

Get in touch

Saul Matthews

VP Sales

Challenges in offshore cable condition monitoring

Cable failures remain the single largest operational cost in offshore wind. Most power cable faults can be traced back to issues with terminations, where jointing and earthing can be vulnerable to degradation over time. Monitoring sheath currents and temperatures in these terminations and their screen connections provides early and economical failure warnings across every cable in one retrofittable, online monitoring system.

Our solution

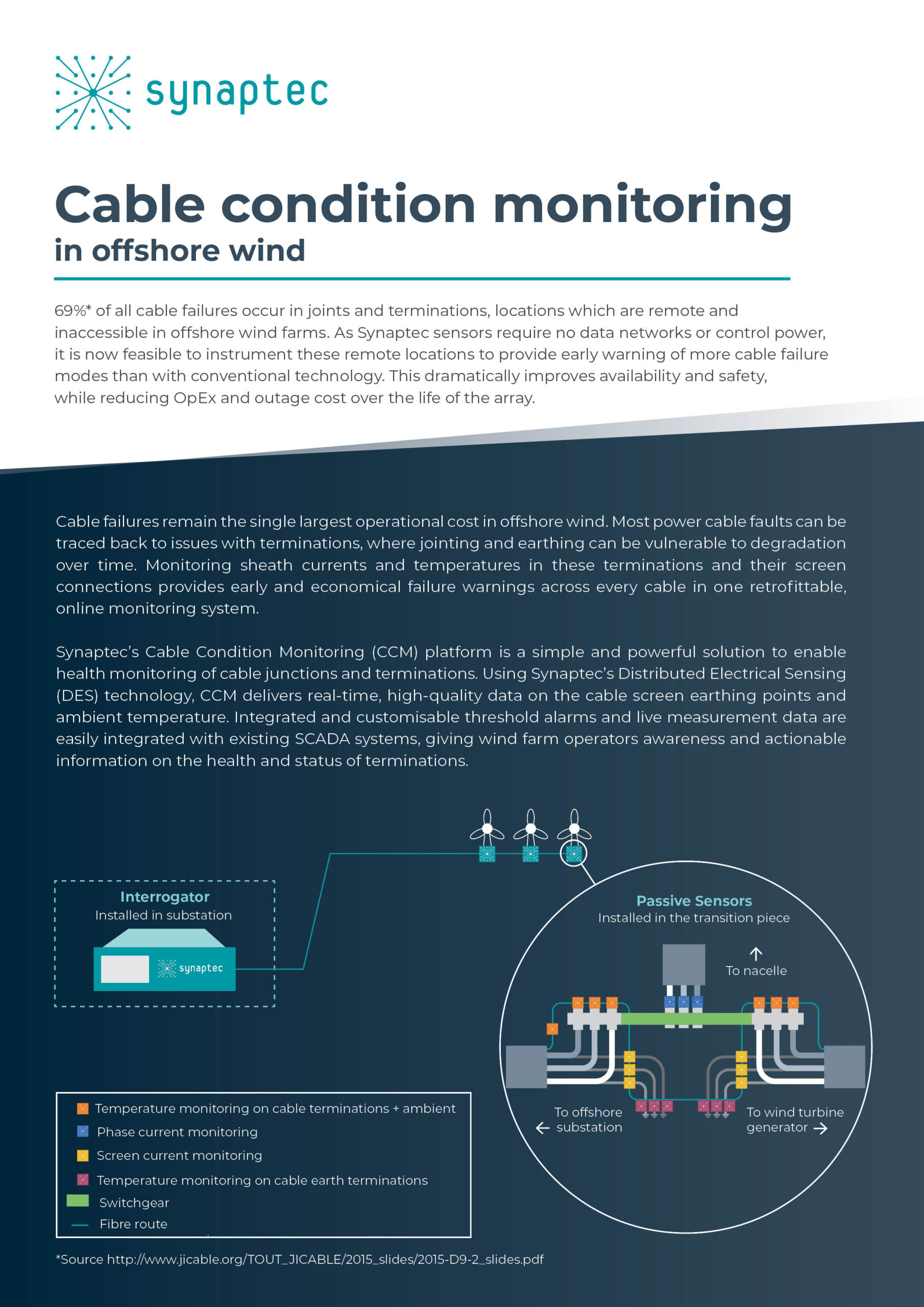

Synaptec’s Cable Condition Monitoring (CCM) platform is a simple and powerful solution to enable health monitoring of cable junctions and terminations. Using Synaptec’s Distributed Electrical Sensing (DES) technology, CCM delivers real-time, high-quality data on the cable screen earthing points and ambient temperature. Integrated and customisable threshold alarms and live measurement data are easily integrated with existing SCADA systems, giving wind farm operators awareness and actionable information on the health and status of terminations.

Synaptec’s unique Distributed Electrical Sensing (DES) technology leverages existing optical fibres to instrument up to 21 mechanical or up to 30 electrical sensors over a 60 km range.

Synaptec sensors do not require data networks, control power, expensive civil works, or time sources at any measurement location, taking as little as 30 minutes per sensor to install.

Current measurements are IEC 60044/IEC 61869 compliant. Temperature measurements are accurate to +/-0.5 °C, allowing the temperature of individual components, such as terminations, to be precisely and discretely monitored. All data – electrical and thermal – are precisely timestamped centrally by the Interrogator module for analysis of fault precursors and trends.

CCM is focused on providing early warning of premature termination failure. CCM is compatible with complementary mid-span optical monitoring technologies such as DTS and DAS and can share the same optical fibre core as those technologies.

Key benefits

- Permanently and synchronously monitors the relationship phase current, sheath current and temperature with passive sensors

- Provides earlier warning of more cable failure modes over longer distances compared to conventional monitoring techniques

- Optimises scheduled maintenance

- Retrofittable

Download Cable Condition Monitoring flyer

Applications

Select an application below to learn more, or contact us to arrange a free workshop on your particular needs.

Cable condition monitoring in offshore wind

Electrical stress monitoring

Distributed power quality (DPQ) monitoring

Holistic offshore cable monitoring

Related posts

Euramet

Electricity from renewables is helping reduce the emissions that would otherwise be produced from fossil fuels, but network operators struggle in integrating these more distributed sources of energy. One solution is to use smart grids capable of monitoring and...

Reaction project

CASE STUDY – THE REACTION PROJECT, LEVENMOUTH 2020 1 Offshore wind generation is subject to harsher conditions than onshore wind, which puts a great deal of pressure on the reliability of critical infrastructure. With the increase in the number of offshore wind farms...

A new approach to mixed circuit protection

Following a severe blizzard in 1888, Hugh Grant, the Mayor of New York, decided to start a global trend of undergrounding power cables to avoid storm damage. Today, global use of underground power cables in transmission and distribution ranges from 20% of the UK’s...